Mechanical sector

- Special automatic machines.

- Belt,chain and shutters conveyors.

- Roller conveyors.

- Conveyors in general.

- Mechanical and pneumatics hands.

- Balancing machines.

- Automatic cutting-off machines.

- Trimming and cutting machines.

- Multi-spindle boring machines.

- Mechanical and hydraulics lifting units.

- Packing and packaging machines.

- Pots polishing machines.

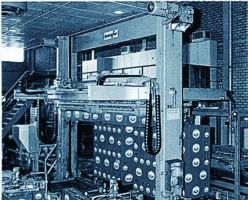

- Automatic hot pressing machines.

- Trolleys and cars powered by linear motors.

- Loading and unloading lines for sintering ovens.

- Autoamtion for industry.

- Cutting,punch and die-casting moulds.

- Sintering moulds.

- Special numerically controlled machine-tools.

- Machines for ultrasound welding.

- Slitter.